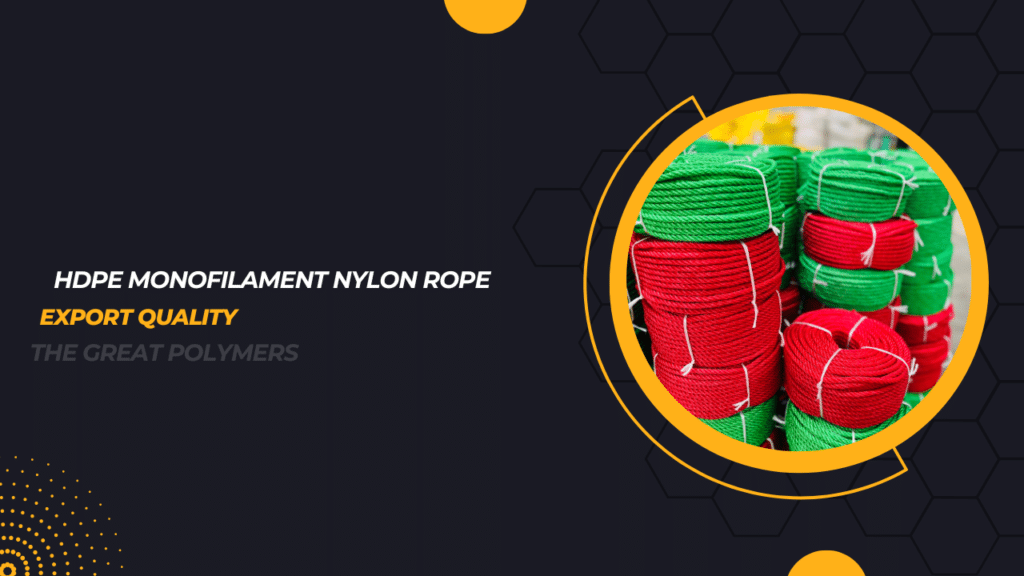

Introduction

HDPE Monofilament Nylon Rope is a versatile and durable tool used in various industries and everyday activities. This article explores the properties, applications, advantages, and maintenance of HDPE Monofilament Nylon Rope, providing insights into why it’s a preferred choice for many.

Properties and Characteristics

HDPE Monofilament Nylon Rope is renowned for its exceptional strength and durability. Crafted from high-density polyethylene (HDPE) and nylon, it exhibits superior resistance to abrasion and stretching, ensuring longevity even in demanding conditions. Its weather-resistant nature makes it suitable for both indoor and outdoor use, withstanding harsh UV rays and extreme temperatures. Additionally, its floatability makes it ideal for marine applications, ensuring buoyancy and ease of use in water.

Common Applications

This type of rope finds extensive use across various industries and activities. In marine settings, it serves as mooring lines, anchor lines, and towing lines due to its strength and resistance to saltwater corrosion. Outdoor enthusiasts rely on HDPE Monofilament Nylon Rope for camping, hiking, and climbing, thanks to its reliability and versatility. Moreover, in agriculture and farming, it’s utilized for securing loads, constructing fences, and supporting plants.

Advantages Over Other Materials

Compared to traditional ropes made from natural fibers or synthetic materials, HDPE Monofilament Nylon Rope offers several advantages. Its superior strength-to-weight ratio ensures optimal performance without adding unnecessary bulk. Unlike natural fibers, it doesn’t rot or decay when exposed to moisture, making it a more durable choice for outdoor use. Additionally, it maintains its integrity even when subjected to heavy loads or rough handling, providing peace of mind in challenging environments.

Choosing the Right HDPE Monofilament Nylon Rope

Selecting the appropriate rope depends on specific requirements and applications. Consider factors such as diameter, length, and weight capacity to ensure compatibility with intended tasks. Thicker ropes offer greater strength and durability, suitable for heavy-duty applications, while thinner ropes provide flexibility and lighter weight for more delicate tasks. Assess weight capacity to determine the rope’s maximum load-bearing capacity, ensuring safety and reliability during use.

Maintenance Tips

To prolong the lifespan of HDPE Monofilament Nylon Rope, proper maintenance is essential. Regularly inspect the rope for signs of wear, fraying, or damage, and replace any compromised sections promptly. Clean the rope with mild soap and water to remove dirt and debris, avoiding harsh chemicals that may weaken the fibers. Store the rope in a dry, well-ventilated area away from direct sunlight and moisture to prevent deterioration.

Safety Precautions

While HDPE Monofilament Nylon Rope is known for its strength and reliability, it’s crucial to observe safety precautions during use. Always wear appropriate protective gear, such as gloves and eyewear, when handling ropes to prevent injury. Avoid exceeding the rope’s weight capacity or using it in conditions beyond its specified limitations. Inspect knots and connections regularly to ensure they’re secure and properly tied, minimizing the risk of accidents or failure.

Environmental Impact

As with any synthetic material, the environmental impact of HDPE Monofilament Nylon Rope must be considered. While it offers durability and longevity, it’s essential to dispose of old or damaged ropes responsibly. Explore recycling options or repurpose old ropes for non-critical tasks to minimize waste and environmental harm. Additionally, manufacturers are increasingly exploring eco-friendly alternatives and sustainable production methods to reduce the environmental footprint of synthetic ropes.

Conclusion

HDPE Monofilament Nylon Rope stands as a testament to innovation and reliability in the world of ropes and cords. With its exceptional strength, durability, and versatility, it has become an indispensable tool across various industries and activities. By understanding its properties, applications, and maintenance requirements, users can harness the full potential of HDPE Monofilament Nylon Rope while minimizing risks and maximizing safety.

Conclusion

In the realm of utility tools, few can rival the versatility and durability of HDPE Monofilament Nylon Rope. From outdoor adventures to industrial applications, its robust construction and reliability make it an essential addition to any toolkit. Embrace the confidence that comes with knowing you have a dependable ally by your side, ready to tackle any challenge with ease.

FAQs

- Is HDPE Monofilament Nylon Rope suitable for heavy lifting?

- Yes, HDPE Monofilament Nylon Rope is known for its high strength-to-weight ratio, making it suitable for heavy lifting and towing applications.

- Can HDPE Monofilament Nylon Rope be used in saltwater environments?

- Absolutely, HDPE Monofilament Nylon Rope is resistant to saltwater corrosion, making it ideal for marine applications such as mooring lines and anchor ropes.

- How should I store HDPE Monofilament Nylon Rope when not in use?

- Store the rope in a dry, well-ventilated area away from direct sunlight and moisture to prevent deterioration and maintain its integrity.

- Can HDPE Monofilament Nylon Rope be repaired if damaged?

- Minor damage such as fraying or small cuts can often be repaired using appropriate splicing techniques. However, significant damage may require replacing the affected sections or the entire rope.

- What are some alternative uses for old HDPE Monofilament Nylon Rope?

- Old ropes can be repurposed for various tasks such as crafting, gardening, or DIY projects. Additionally, some recycling facilities accept synthetic ropes for processing into new materials.