Introduction

Polyethylene (PE) ropes are essential tools in various industries, offering durability, flexibility, and reliability. Among the many options available, the 100-yard blue PE rope stands out for its specific applications and benefits. This article explores everything you need to know about these ropes, from their manufacturing process to their numerous uses and advantages.

What is PE Rope?

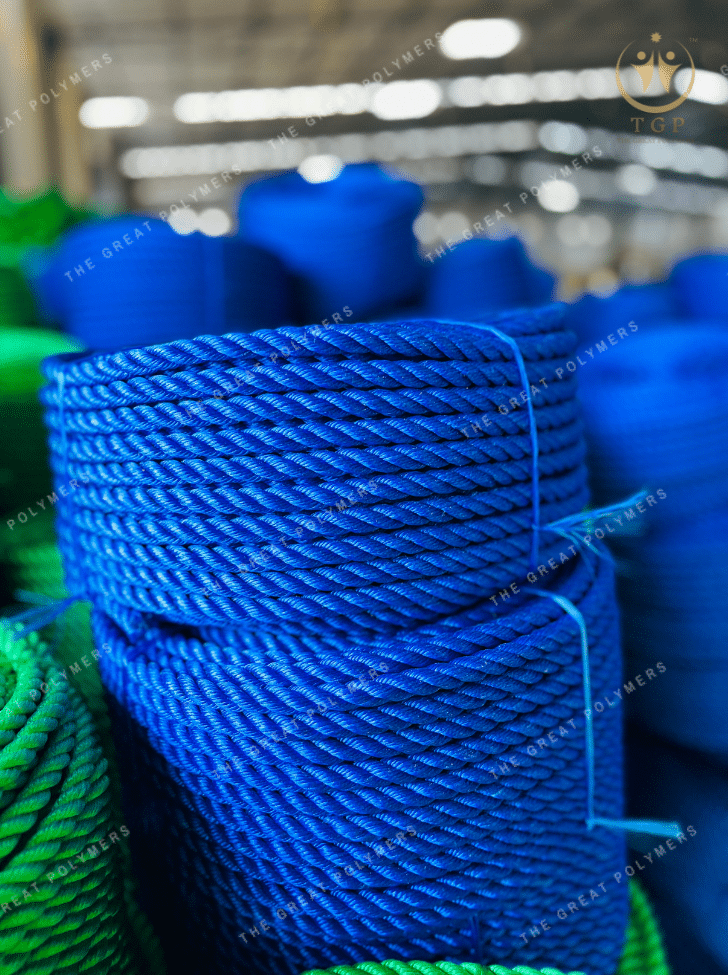

PE rope, short for polyethylene rope, is a type of synthetic rope made from polyethylene fibers. These ropes are known for their strength, resistance to chemicals, and low water absorption. PE ropes are widely used in industries like marine, construction, and agriculture due to their versatility and reliability.

Why Choose a 100-Yard PE Rope?

A 100-yard PE rope offers the perfect balance between length and usability. It’s long enough to be used in various applications without being cumbersome to handle. This length is ideal for tasks requiring extended reach, such as mooring boats, setting up tents, or securing loads.

The Significance of Blue Color in PE Ropes

The blue color in PE ropes is not just for aesthetics; it serves practical purposes as well. Blue is highly visible against most backgrounds, making it easier to spot the rope in different environments. This visibility is crucial in marine settings and for safety purposes in industrial applications.

Manufacturing Process of PE Ropes

The manufacturing of PE ropes involves several steps:

- Raw Materials and Sourcing: High-quality polyethylene is sourced to ensure the final product’s strength and durability.

- Extrusion: Polyethylene pellets are melted and extruded into thin strands.

- Twisting and Braiding: These strands are then twisted or braided together to form the rope, enhancing its strength and flexibility.

- Dyeing: The rope is dyed blue using colorfast dyes to ensure the color remains vibrant and does not fade over time.

- Quality Control: The finished ropes undergo rigorous testing to meet industry standards.

Quality Control in PE Rope Manufacturing

Quality control is a critical aspect of PE rope manufacturing. Manufacturers adhere to strict standards and certifications to ensure their products’ safety and reliability. Testing procedures include tensile strength tests, chemical resistance tests, and UV stability tests to guarantee that the ropes perform well in various conditions.

Top Manufacturers of 100-Yard Blue PE Ropes

When choosing a PE rope, it’s important to consider reputable manufacturers. Top manufacturers have a proven track record of producing high-quality ropes that meet industry standards. Some leading manufacturers offer customization options, allowing customers to specify the rope’s thickness, color, and length according to their needs.

Advantages of Buying Directly from Manufacturers

Purchasing directly from manufacturers offers several benefits:

- Cost Benefits: Eliminating middlemen reduces costs, making the ropes more affordable.

- Customization Options: Direct manufacturers can tailor the ropes to specific requirements, providing more flexibility and options.

Environmental Impact of PE Ropes

While PE ropes are highly durable and versatile, their environmental impact cannot be ignored. Manufacturers are increasingly adopting sustainable practices, such as using recycled materials and implementing efficient manufacturing processes to reduce waste. Proper recycling and disposal of PE ropes are crucial to minimize their environmental footprint.

Innovations in PE Rope Manufacturing

Technological advancements have led to significant innovations in PE rope manufacturing. These include improved extrusion techniques, better braiding machinery, and more sustainable dyeing processes. Future trends indicate a move towards more eco-friendly materials and manufacturing methods.

Applications of 100-Yard Blue PE Ropes

PE ropes have a wide range of applications:

- Marine and Boating Uses: Ideal for mooring, towing, and anchoring due to their strength and resistance to saltwater.

- Camping and Outdoor Activities: Used for setting up tents, tarps, and securing gear.

- Industrial and Commercial Applications: Employed in construction, agriculture, and various other industries for tasks like securing loads and setting up barriers.

How to Choose the Right PE Rope for Your Needs

Selecting the right PE rope depends on several factors:

- Strength: Ensure the rope can handle the required load.

- Flexibility: Consider the rope’s flexibility for ease of handling.

- UV Resistance: Choose ropes with UV resistance for outdoor use.

Comparing different types of PE ropes based on these factors can help in making an informed decision.

Maintenance and Care of PE Ropes

Proper maintenance extends the lifespan of PE ropes:

- Cleaning: Regularly clean the ropes to remove dirt and debris.

- Storage: Store in a cool, dry place away from direct sunlight.

- Inspection: Periodically inspect for signs of wear and tear, and replace damaged sections promptly.

Avoiding common mistakes like dragging the rope over rough surfaces can prevent premature wear.

Customer Reviews and Testimonials

Customer reviews and testimonials provide valuable insights into the performance and reliability of PE ropes. Many users highlight the durability and versatility of 100-yard blue PE ropes, sharing their positive experiences in various applications.

Conclusion

In conclusion, the 100-yard blue PE rope is a versatile, durable, and reliable tool suitable for a wide range of applications. From marine uses to industrial tasks, this rope offers excellent performance and visibility. By choosing a reputable manufacturer and following proper maintenance practices, users can ensure the longevity and effectiveness of their PE ropes.

FAQs

What is PE rope made of? PE rope is made of polyethylene fibers, known for their strength, durability, and resistance to chemicals.

How strong is PE rope compared to other materials? PE rope is strong and offers good resistance to abrasion and chemicals, making it comparable to other synthetic ropes like nylon and polypropylene.

Can PE rope be used in extreme weather conditions? Yes, PE rope is resistant to UV rays, moisture, and various chemicals, making it suitable for extreme weather conditions.

How do I know if a PE rope is of good quality? Good quality PE ropes meet industry standards, have consistent braiding or twisting, and come from reputable manufacturers with proper certifications.

Are there any safety concerns with using PE ropes? While PE ropes are generally safe, it’s important to use them within their specified load limits and regularly inspect them for signs of wear and tear.